PURE MONOMER RESIN

In adhesives, pure monomer resins are used in hot melts, pressure sensitive tapes and labels, construction mastics, and many specialty applications. Pure monomer resins are also excellent tackifiers and compatibilization aids in the rubber market. In addition, pure monomer resins have found utility in coatings, investment wax casting compounds, thermoplastic/thermoplastic elastomers (TPE) modification, hydrophobic sealants, and coatings.

Pure monomer resins are the primary matrix material in adhesives, providing a structural backbone and contributing to the overall strength and durability of adhesives.

PMR are chemicals with polymerization capabilities that are employed in variety of industries, especially in polymerization process. These resins are composed of one type of molecule which makes them highly reactive and capable of forming long molecular chains. This leads to robust, long lasting and adaptable material.

PMR applications include serving as the primary binder in sealants due to its distinctive copolymerization properties. These properties make them compatible with broad spectrum of polymers. Polyethylene, Styrene-Butadiene, acrylic, polyester, aromatic isocyanate etc.

Increase in construction, automotive production and expansion of packaging industry is generating demand for adhesives and sealants and that will help in steady growth of PMR.

Phenolics derived from PMR helped to grow business of printing ink for durable media and also in woodworking. Formaldehyde based resins such as Urea formaldehyde and Melamine formaldehyde revolutionized manufacturing of wood adhesives and particle boards facilitating surge in construction, housing and furniture.

PMR when used during manufacturing of tires can improve grip force at the same time maintaining fuel efficiency.

Epoxy resins have emerged as the front runner in high performance coatings. Superior adhesion, water and chemical resistance made it 1st choice for marine paints, aerospace and industrial floors. PMR are prerequisite in many of such polymer and plastics synthesis.

PMR are also very useful in healthcare sector. They help in manufacturing of encapsulated drugs and releasing them over regular period of time. It helps in improvement of treatment efficacy and reduces side effects. PMR can be used to target specific cell and tissues in the body.

During manufacturing of PMR several volatile organic and solid waste is generated. It also emits lots of green house gases during production which is a concern from eco-friendly point of view.

Pure monomer resins have a unique molecular structure that gives them unique properties compared to other hydrocarbon resins. The presence of the methyl group on the alpha-carbon of AMS monomer gives the resulting resin improved heat resistance, chemical resistance, and electrical insulation properties.

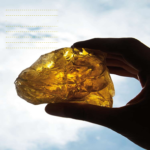

Pure monomer resins, also known as alpha methyl styrene resins, are a type of hydrocarbon resin that is derived from the polymerization of alpha-methyl styrene (AMS) monomer. AMS is a derivative of styrene that contains a methyl group on the alpha-carbon, which gives it unique properties compared to regular styrene.

The chemistry of pure monomer resins is characterized by the polymerization of AMS monomer through a free radical mechanism. During the polymerization process, the double bond on the styrenic ring of AMS is broken, and the monomers are joined together to form a polymer chain.

Alpha-Methyl styrene, like styrene, is an aromatic hydrocarbon compound capable of addition polymerization.

Alpha-methyl styrene or 2-phenylpropene is a colourless or slightly yellow hydrocarbon, flammable aromatic organic liquid having an unpleasant odour. It is practically insoluble in water. It is a by-product in the production of phenol according to the cumene process.

Pure Monomer Resin are compatible with various polymers, including high and low vinyl acetate EVA, acrylics, SBR, SIS, and SBS. This allows formulation flexibility in hot-melt, water-based, and solvent-based adhesives.

AMS / PMR is a water white aromatic hydrocarbon resin with superior oxidative stability. It is used to modify styrene end blocks of SBC and in EVA adhesives. It is done in order to improve cohesion and high temperature resistance. This resin may be used as a reinforcing agent in modifying the styrene end blocks of styrenic block-copolymers, in order to improve cohesion and high temperature resistance. It can also be used as a tackifier for EVA based hot melt adhesives. The phenolic component improves compatibility with high-polarity polymers. The low Tg of these resins improves elasticity at low temperature.

HROC offers MKOREZ range of PMR from KOLON Inds, Korea for these applications.