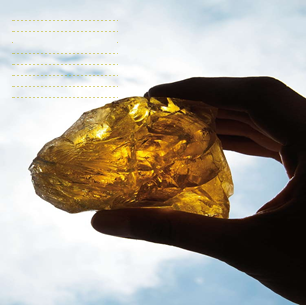

Rosin is also called colophony or Greek pitch, is a solid form of resin obtained from pines and some other plants, mostly conifers, produced by heating fresh liquid resin to vaporize the volatile liquid terpene components. It is semi-transparent and varies in color from yellow to black. At room temperature rosin is brittle, but it melts at stove-top temperature. It chiefly consists of various resin acids, especially abietic acid. It is an FDA approved food additive.

Rosin mainly is used for enhancing the strength, elasticity, and viscosity of adhesive. Gum Rosin can be used as coating material for release control fertilizer. Rosin can be converted into abietyl amine acetate for killing algae, bacteria, mildew, mollusc and others pest.

Rosin is brittle and friable, with a faint piny odour. It is typically a glassy solid, though some rosins will form crystals, especially when brought into solution.[6] The practical melting point varies with different specimens, some being semi-fluid at the temperature of boiling water, others melting at 100 °C to 120 °C (210°F to 250°F). It is very flammable, burning with a smoky flame, so care should be taken when melting it. It is soluble in alcohol, ether, benzene and chloroform. The gum rosin resin usually consists of 90% acidic resin and 10% neutral substance. The resin acid is isomer with abietic acid. The rest is dehydroabietic acid and dehydroabietic acid. The glycerine ester resin is obtained from the gum rosin resin by esterification with glycerine.

Rosin consists mainly of abietic acid, and combines with caustic alkalis to form salts (rosinates or pinates) that are known as rosin soaps. In addition to its extensive use in soap making, rosin is largely employed in making varnishes (including fine violin varnishes), sealing wax and various adhesives. It is also used for preparing shoemakers’ wax, for pitching lager beer casks, and numerous other purposes such as providing backing surfaces to tin ware, copper ware, or even silver and gold vessels when embossing or engraving them. Its relatively low melting point, and firm solid form allows liquid rosin to be poured into the vessel, and when cooled allows embossing or engraving of the vessel without deforming the vessel – even if it has a skin which is quite thin. Afterwards, the object can be reheated in an oven, and the rosin poured out for reuse. Any remaining rosin film can easily be rinsed away with alcohol or other solvents.

Rosin is also sometimes used as internal reinforcement for very thin-skinned metal objects – things like silver, copper or tin plate candlesticks, or sculptures, where it is simply melted, poured into a hollow thin-skinned object, and left to harden.

The type of rosin used with bowed string instruments is determined by the diameter of the strings. Generally, this means that the larger the instrument is, the softer the rosin should be. For instance, double bass rosin is generally soft enough to be pliable with slow movements. A cake of bass rosin left in a single position for several months will show evidence of flow, especially in warmer weather.

Rosin is an ingredient in printing inks, photocopying and laser printing paper, varnishes, adhesives (glues), soap, paper sizing, soda, soldering fluxes, and sealing wax.

Rosin can be used as a glazing agent in medicines and chewing gum. It is denoted by E number E915. A related glycerol ester (E445) can be used as an emulsifier in soft drinks. In pharmaceuticals, rosin forms an ingredient in several plasters and ointments.

In industry, rosin is a flux used in soldering. The lead–tin solder commonly used in electronics has 1 to 2% rosin by weight as a flux core, helping the molten metal flow and making a better connection by reducing the refractory solid oxide layer formed at the surface back to metal. It is frequently seen as a burnt or clear residue around new soldering.

A mixture of pitch and rosin is used to make a surface against which glass is polished when making optical components such as lenses.

Rosin is added in small quantities to traditional linseed oil/sand gap fillers (“mastic”), used in building work.

When mixed with waxes and oils, rosin is the main ingredient of mystic smoke, a gum which, when rubbed and suddenly stretched, appears to produce puffs of smoke from the fingertips.

Rosin and its derivatives also exhibit wide-ranging pharmaceutical applications. Rosin derivatives show excellent film forming and coating properties They are also used for tablet film and enteric coating purpose. Rosins have also been used to formulate microcapsules and nanoparticles.

Glycerol, sorbitol, and mannitol esters of rosin are used as chewing gum bases for medicinal applications.

Rosin is the resinous constituent of the oleo-resin exuded by various species of pine, known in commerce as crude turpentine. The separation of the oleo-resin into the essential oil (spirit of turpentine) and common rosin is accomplished by distillation in large copper stills. The essential oil is carried off at a temperature of between 100 °C (212 °F) and 160 °C (320 °F), leaving fluid rosin, which is run off through a tap at the bottom of the still, and purified by passing through straining wadding. Rosin varies in color, according to the age of the tree from which the turpentine is drawn and the degree of heat applied in distillation, from an opaque, almost pitch-black substance through grades of brown and yellow to an almost perfectly transparent colorless glassy mass. The commercial grades are numerous, ranging by letters from A (the darkest) to N (extra pale), superior to which are W (window glass) and WW (water-white) varieties, the latter having about three times the value of the common qualities.

Tall oil rosin is produced during the distillation of crude tall oil, a by-product of the kraft paper making process.

When pine trees are harvested “the resinous portions of fallen or felled trees like longleaf and slash pines, when allowed to remain upon the ground, resist decay indefinitely. This “stump waste”, through the use of destructive distillation or solvent processes, can be used to make products including rosin. This type of rosin is typically called wood rosin.

Because the turpentine and pine oil from destructive distillation “become somewhat contaminated with other distillation products”, solvent processes are commonly used. In this process, stumps and roots are chipped and soaked in the light end of the heavy naphtha fraction (boiling between (90 °C (194 °F) and 115 °C (239 °F) from a crude oil refinery. Multi-stage counter-current extraction is commonly used. In this process, fresh naphtha first contacts wood leached in intermediate stages, and naphtha laden with rosin from intermediate stages contacts unleached wood before vacuum distillation to recover naphtha from the rosin, along with fatty acids, turpentine, and other constituents later separated through steam distillation. Leached wood is steamed for additional naphtha recovery prior to burning for energy recovery. After the solvent has been recovered, “the terpene oils are separated by fractional distillation and recovered mainly as refined turpentine, dipentene, and pine oil. The non-volatile residue from the extract is wood rosin of rather dark color. Upgrading of the rosin is carried out by clarification methods that generally may include bed-filtering or furfural-treatment of rosin-solvent solution.

On a large scale, rosin is treated by destructive distillation for the production of rosin spirit, pinoline and rosin oil. The last enters into the composition of some of the solid lubricating greases, and is also used as an adulterant of other oils.

Disproportionated rosin has good oxidation resistance, low brittleness, high thermal stability and light color, and maintains a high softening point, even higher than the original rosin due to the elimination of turpentine oils during disproportionation at 200 to 240 °C. It is applied in several industries: adhesives (hot-melt and pressure-sensitive adhesives), solder flux, printing inks, paper neutral-size – after saponification – and more. It has some important applications in the polymeric industry where abietic acid presence is not adequate, because it acts as an inhibitor (amounts as low as 0.5% in abietic acid are looked up) and very high percentages in dehydroabietic acid are desired.

The chief region of rosin production includes Indonesia, southern China (such as Guangdong, Guangxi, Fujian, Yunnan and Jiangxi), and the northern part of Vietnam. Chinese rosin is obtained mainly from the turpentine of Masson’s pine Pinus massoniana and slash pine P. elliottii. The latter species is native to the southeastern U.S., but is now widely planted in tree plantations in China.

The South Atlantic and eastern Gulf states of the United States is a second chief region of production. American rosin is obtained from the turpentine of longleaf pine Pinus palustris and loblolly pine P. taeda. In Mexico, most of the rosin is derived from live tapping of several species of pine trees, but mostly Pinus oocarpa, Pinus leiophylla, Pinus devoniana and Pinus montezumae. Most production is concentrated in the west-central state of Michoacán.

Different Grades of Gum Rosin

Disproportionated Gum Rosin

DPR is a further processed version of normal Gum Rosin, with an even higher quality. Gum Rosin goes through a process called as disproportionation to further purify the matter and intensify the tackifying and emulsifying qualities of Rosin.

Description

The grades of DPR vary depending upon what grade of Gum Rosin is used to produce it. The most popular type is our DPR CG 700 which is made from Gum Rosin WW and is of the highest quality possible.

Chemical Codes (CAS No./ HS No.)

CAS No.8050-09-7

Molecular Formula: C19H27COO

Application/Usage

DPR is extensively used in the adhesives, paints, pigments (organic, dyechems and inorganic), SBR and ink industries as a first stage emulsifier and tackifier. It lends a persistent increase in quality to the final product.

Developments are also taking place in the Butyl mastic and other adhesive industries. Widely preferred for the top and higher grades of the particular product.

It is the most important component for emulsification in SBR, rubber, ABS industries.

Specifications

Obtained by isomerizing Gum Rosin using a catalyst.

|

Appearance |

Light yellow solid |

|

Color(Gardner),max. |

8 |

|

Abietic Acid (%), max. |

0 |

|

Dehydroabietic Acid (%), min. |

54.0 |

|

Softening Point |

75-85 |

|

Acid No. (mg KOH/g) |

150-165 |

|

Unsaponifiable Material (%), max. |

10.0 |

Glycerol ester of wood rosin

Glycerol ester of wood rosin is a complex mixture of glycerol di- and triesters of resin acids from wood rosin, with a residual fraction of glycerol monoesters. Besides these esters, neutrals (non-acidic saponifiable and unsaponifiable substances) and residual free resin acids are present. It is obtained by the solvent extraction of aged pine stumps (Pinus palustris (longleaf) and Pinus elliottii (slash) species) followed by a liquid-liquid solvent refining process. The refined wood rosin composed of approximately 90% resin acids and approximately 10% neutrals. The resin acid fraction is a complex mixture of isomeric diterpenoid monocarboxylic acids having the typical empirical formula C20H30O2, of which the main component is abietic acid. The substance is purified by steam stripping or by counter current steam distillation.

Glycerol ester of gum rosin, deodorized

Glycerol Ester of Gum Rosin (GEGR), also called as Glyceryl Rosinate, or Ester Gum, is an oil-soluble food additive. which esterified with Rosin and edible Glycerol.

Its high density helps keep oils in suspension in water and this property is the reason why it is often used as a beverage stabilizer. It is widely used as a base in the production of chewing-gum. It also serves as an alternative to brominated vegetable oil in citrus oil flavored soft drinks. In some cases, both ingredients are used together.

Identification

|

Synonyms |

Glyceryl Rosinate | ESTER GUM |

|

CAS |

8050-31-5 |

|

HSN CODE |

38069000 |

|

Molecular Formula |

C63H95O6 |

|

Molecular Weight |

760 ± 20 |

Application & Uses

- as anti-oxidant and softening with good taste in the production of SBR or polyvinyl acetate-based chewing-gum and bubble gum.

- as emulsification stabilizer in soft drink

- as tackifier in depilatory and Cosmetic industry

- applied on coated urea fertilizer for tobacco

- as a thixotropic agent of pesticide dispersion

Features & Benefits

- Its high density helps keep oils in suspension in water and this property is why it is often used as a beverage stabilizer.

- It also serves as an alternative to brominated vegetable oil in citrus oil flavoured soft drinks.

- Totally soluble in aromatic, aliphatic and chlorinated solvents, Not soluble in alcohols, ketones (except butanol and MEK)

Specification

|

ITEM |

VALUE |

|

Colour, Gardner |

7 to 8 |

|

Softening Point, R&B, °C |

82 to 90 |

|

Heavy metals, PB, mg/kg |

20 max |

|

Acid Value, mgKOH/g |

3 to 8 |

|

Arsenic, mg/kg |

2 max |

|

Ash, % |

0.1 max |

|

Solubility, with Benzene 1:1 |

Clear |

Pentaerythritol ester of stabilized rosin

This ester of hydrogenated gum rosin is a medium hard, pale, thermoplastic resin designed primarily as a tackifying resin for various types of polymer and elastomer-based adhesives. It is a pentaerythritol ester of a rosin that has been stabilized by hydrogenation. In adhesive formulations, it contributes improved resistance to oxidation, greater heat stability, better retention of color, and greater retention of tack-imparting properties than ordinary rosin ester resins. Excellent resistance to oxidation High softening point, Light color, Low odor Thermoplastic hydrogenated resin Wide solubility and compatibility range.

Properties

Ring and Ball Softening Point 101 °C ASTM E 28

Color, Gardner 8 ASTM D 6166, 50% solids in toluene

Acid Number 15 mg KOH/g ASTM D 465

Density at 25°C 1.07 kg/dm³

Melt Viscosity at 140°C 2600 cP/Melt Viscosity at 160°C 480 cP /Melt Viscosity at 180°C 110 cP

Applications

Caulks and Sealants, Assembly, Packaging specialities, Carpet, Packaging, Graphic inks, Film Modification, Hygiene Adhesives, Labels, Tapes, Plastic Modification, Other coatings, Road marking, Roofing, Other adhesives , Specialty Tapes, Tire components, Wire and cable, Adhesives Compatibility and Solubility Compatible at all ratios, or in limited but practically useful proportions, with other resins, waxes etc.

Triethylene Glycol Rosinate (CAS 8050-25-7)

Triethylene Glycol Rosinate, also called Triethylene Glycol Ester of Rosin, is produced via a special process that delivers light initial color and product stability. It is a pale, viscous liquid with tackifying and plasticizing characteristics.

Application & Uses

- used as tackifying resin for hot melt adhesives, imparting high tack and flexibility.

- used as flooring, pressure sensitive and solvent based adhesives.

- used as depilatory waxes

Features & Benefits

- Pale Yellow Transparent Sticky Liquid

- Insoluble in water;

- Soluble in aromatic and aliphatic hydrocarbon solvents such as: acetones, benzene, ethyl acetate, ethanol, etc